ABOUT US

Welcome To Aqozone

AQOZONE INDUSTRIES, specializes in Ozone systems, integration of automated turnkey systems for most applications involving water and air purification. We supply ozone systems, ozone generators, and ozone-related accessories along with providing service, repair, and maintenance services

We are the ISO 9001,2005 accredited company with MSME registered

Vision

To be a global leader in sustainable ozone, UV-based solutions, enhancing the quality of life and safeguarding the environment.

Mission

Our mission is to develop innovative ozone-UV technologies that address critical challenges across industries. We strive to create cleaner air, purer water, and healthier spaces through our ozone -UV products and services for the future society.

Core values

our best services!

Products Information

At Aqozone Industries we understand customer present and future needs and design the machine.

We ensure that the customer purpose is served and meets his expectations.

Ozone

The Ozonation Process

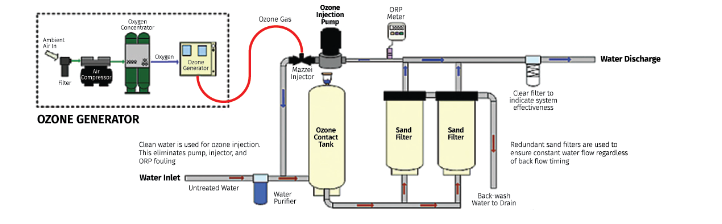

This exposes a stream of air or oxygen to either UV light or to a high voltage electrical discharge, the method known as corona discharge. The corona discharge method is typically preferred and takes place by breaking apart the two oxygen atoms of an oxygen molecule (O 2 ), then charging one of those atoms to another oxygen molecule, thus creating ozone (O 3 ) molecules. Unfortunately, ozone cannot be stored or packaged because of its instability. Its effectiveness will depend on CT, which will be explained later.

In a water treatment application, the raw water passes through a venturi injector, which creates a vacuum and pulls the ozone gas into the water. An alternate method is bubble diffusion, where air bubbles up through the water being treated. Since the ozone will react with other contaminants or metals to create insoluble metal oxides, post filtration is sometimes required.

Ozone CT Explained

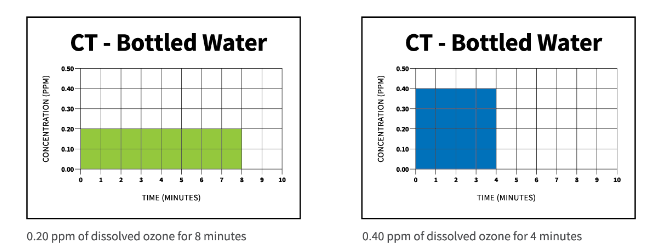

CT is the product of residual disinfectant concentration (C) in mg/l and the corresponding disinfectant contact time (T) in minutes. In other words, ozone CT is the dissolved ozone concentration multiplied by the contact time. Some sanitizing treatments with ozone can be accomplished very quickly, but other treatments will require higher levels of ozone or longer contact time in the water. This contact time is required for the dissolved ozone to oxidize organic contaminants and disinfect the water.

This CT value is assumed to be unitless. To assure a given level of disinfection is obtained, either the ozone concentration can be held constant while the time is varied or vice-versa. For example, a CT value the bottled water industry generally uses is 1.6. This means the dosage rate is 1.6 mg/l minutes. Ozonation can happen at 0.2 ppm for 8 minutes or 0.4 ppm for 4 minutes. Either approach yields a final CT of 1.6.