Ozone, also known as tri-oxygen, has the chemical formula O3 and is composed of three oxygen atoms. Ozone gas is naturally unstable at normal atmospheric conditions which means that in commercial applications, ozone must be made on-site using an ozone generator. The lifetime of ozone in water depends on various factors including water temperature, ozone concentration, and the composition of the water itself. Ozone is one of the most power oxidation tools water treatment professionals have for purification and disinfection.

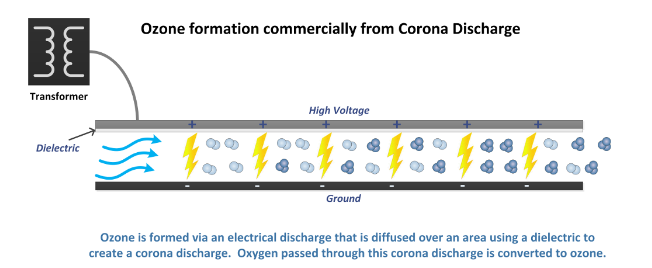

Commercial Ozone Production from Electrical Discharge

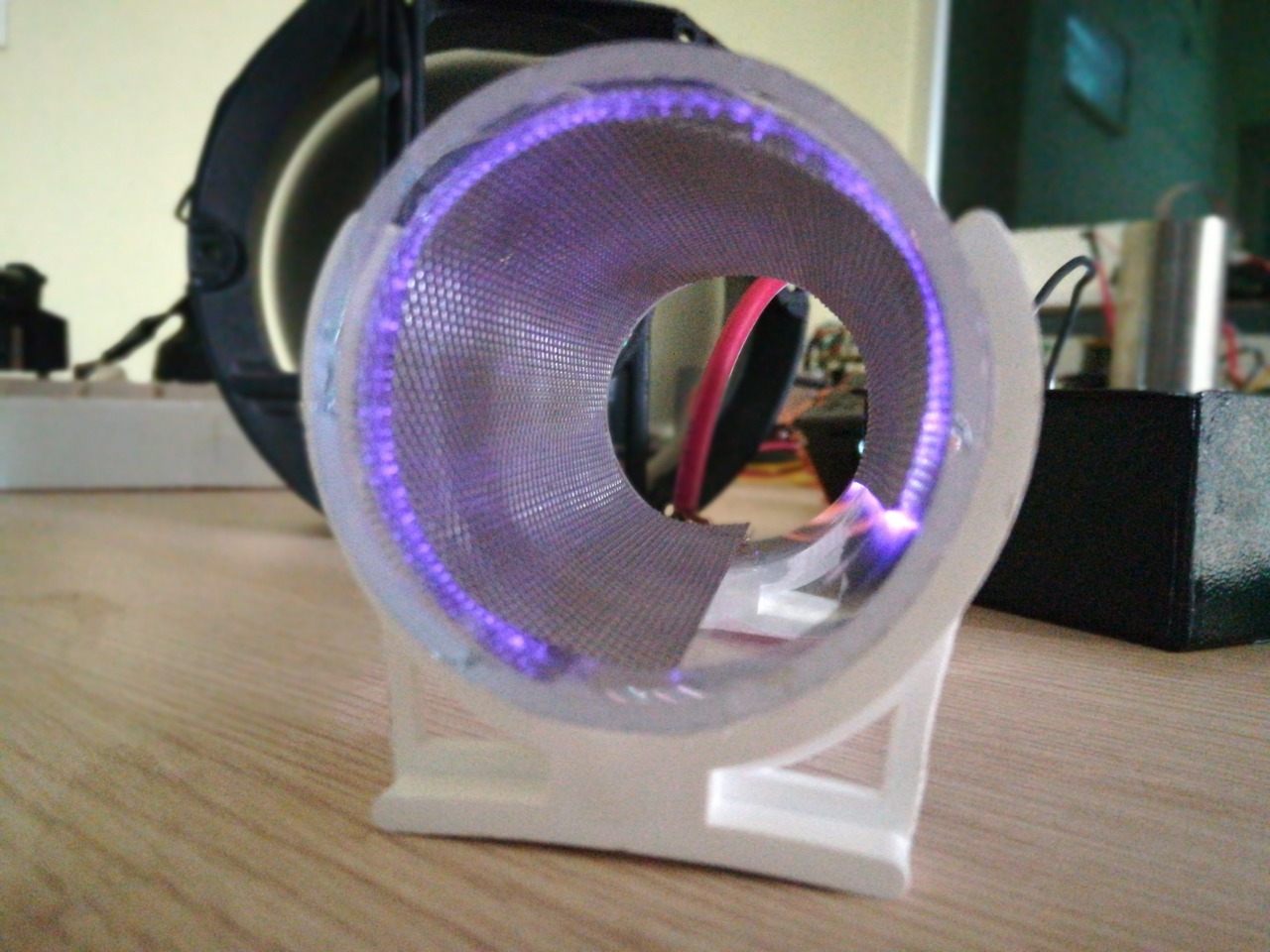

The most common method of producing ozone commercially and industrially is electrical discharge, or corona discharge. A corona discharge is simply a diffused spark through a dielectric to spread out that electrical discharge to a large area for maximum efficiency.