ETP Plants

What Is an Effluent Treatment Plant (ETP)?

An Effluent Treatment Plant (ETP) is a critical infrastructure in industries that generate wastewater containing hazardous pollutants. Unlike domestic sewage, industrial effluents often contain dyes, oils, heavy metals, and toxic chemicals that can severely harm ecosystems and public health if released untreated.

Industries such as textiles, pharmaceuticals, chemicals, food processing, tanneries, and refineries rely on ETPs to ensure compliance with pollution control norms and sustainability goals.

Types of Treatment Used in ETPs

ETPs typically use a combination of physical, chemical, and biological processes to treat wastewater.

1. Preliminary Treatment

- Purpose: Remove large solids and grit

- Processes: Screening, Sedimentation, Oil and grease traps

2. Primary Treatment

- Purpose: Separate suspended solids and reduce organic load

- Processes: Coagulation and flocculation, Primary sedimentation

3. Secondary (Biological) Treatment

- Purpose: Degrade dissolved organic matter using microorganisms

- Processes: Activated sludge process, Trickling filters, MBBR, SBR

4. Tertiary (Advanced) Treatment

- Purpose: Polish the effluent to meet discharge or reuse standards

- Processes: Filtration (sand, carbon, membrane), Disinfection (chlorination, UV, ozone), Electro-oxidation, Electrocoagulation, Reverse Osmosis (RO)

5. Sludge Treatment

- Purpose: Treat and dispose of sludge generated during treatment

- Processes:

Thickening,

Dewatering,

Drying or incineration

Benefits of ETPs

- Protects water bodies and groundwater

- Ensures legal compliance with pollution norms

- Enables water reuse and resource recovery

- Reduces environmental footprint of industries

Strategic Partnership: Aqozone Industries & Lambert

Aqozone Industries is proud to announce its strategic association with Lambert, a globally respected engineering and infrastructure solutions provider, for the installation and commissioning of advanced Effluent Treatment Plants (ETPs) across key industrial sectors.

This collaboration marks a significant milestone in our mission to deliver sustainable, high-performance water purification systems that meet the evolving demands of modern industry.

What This Partnership Brings

- Turnkey ETP Solutions: From design to commissioning, Aqozone and Lambert jointly deliver fully integrated effluent treatment systems tailored to client-specific requirements.

- Technical Synergy: Aqozone’s expertise in ozone and ultrafiltration technologies complements Lambert’s engineering precision and project execution capabilities

- Global Standards: All installations adhere to international environmental norms and industry best practices, ensuring regulatory compliance and long-term reliability.

- Rapid Deployment: With Lambert’s robust infrastructure and Aqozone’s modular systems, clients benefit from accelerated timelines and seamless commissioning.

Shared Vision for Sustainability

Both organizations are deeply committed to eco-conscious innovation, aiming to reduce industrial water footprints and promote circular water reuse. Our joint ETP installations are designed to:

- Minimize chemical usage

- Reduce sludge generation

- Enable water recycling and ZLD options

Industries We Serve

- Textile & Dyeing

- Pharmaceuticals & Chemicals

- Food & Beverage

- Metal Finishing & Electroplating

- Municipal & Decentralized Systems

Recent Projects

Together, Aqozone and Lambert have successfully commissioned ETP plants for leading clients across India and Southeast Asia, delivering measurable improvements in water quality, operational efficiency, and environmental impact.

This partnership reflects our shared commitment to engineering excellence, environmental stewardship, and client satisfaction.

Advanced Electrochemical Treatment for Industrial Effluents

At Aqozone Industries, we integrate cutting-edge Electro-Oxidation (EO) and Electrocoagulation (EC) technologies into our Effluent Treatment Plants (ETPs) to deliver unmatched purification performance for complex industrial wastewater.

Our Association with Lambert

⚡ Electro-Oxidation (EO): Molecular Breakdown at the Source

Ideal for: High-COD effluents, dyes, pharmaceuticals, pesticides, and non-biodegradable organics

Benefits

- Significant reduction in COD/BOD

- Minimal chemical usage

- Compact footprint and modular scalability

- Environmentally friendly with no secondary pollution

Electro-oxidation is based on the principle of generating strong oxidizing agents at the surface of an anode to degrade pollutants in wastewater. These oxidants break down complex organic molecules into simpler, non-toxic compounds such as carbon dioxide and water.

⚙️ Scientific Principle of Electro-Oxidation

Electro-oxidation (EO), also known as anodic oxidation, is a type of Advanced Oxidation Process (AOP) that uses electrical energy to initiate chemical reactions at the surface of electrodes submerged in wastewater.

1. Electrode Setup

- Anode and cathode connected to a DC power source

- Supporting electrolyte (e.g., NaCl or Na₂SO₄) to improve conductivity

2. Oxidant Generation

- Hydroxyl radicals (•OH): Extremely reactive and non-selective

- Active chlorine species (Cl₂, HOCl, OCl⁻): Formed in presence of chloride ions

3. Pollutant Degradation

- Breakdown of refractory organic compounds

- Formation of intermediates (aldehydes, acids)

- Final products: CO₂, H₂O, inorganic ions

4. Mineralization

The goal is complete mineralization, converting harmful organics into harmless end-products without generating secondary pollution.

🔬 Oxidation Mechanisms

- Direct Oxidation: Pollutants oxidized directly at the anode surface

- Indirect Oxidation: Oxidants formed in solution react away from the electrode

📈 Factors Influencing EO Efficiency

- Electrode material (BDD, graphite, platinum)

- Current density

- Electrolyte type and concentration

- pH and temperature

- Presence of competing ions

Electro-oxidation is especially effective for treating high-COD, toxic, and non-biodegradable wastewater from textiles, pharmaceuticals, and chemical industries.

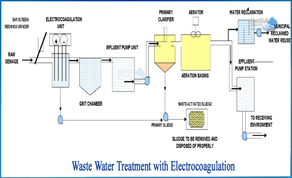

🧲 Electrocoagulation (EC): Clean Separation, Naturally

Electrocoagulation (EC) is an advanced electrochemical process used in wastewater treatment to remove contaminants like suspended solids, heavy metals, oils, and emulsions by generating coagulant ions directly from metal electrodes. It’s eco-friendly, cost-effective, and highly efficient for industrial effluents.

What Is Electrocoagulation?

Electrocoagulation is a chemical-free water treatment technology that uses electricity to dissolve metal electrodes (typically iron or aluminum) into wastewater. These dissolved ions act as coagulants, destabilizing pollutants and causing them to aggregate and settle.

How It Works

- Electrode Setup: A DC power source energizes metal electrodes submerged in the effluent.

- Ion Release: The anode releases metal ions (Fe2+ or Al3+), which hydrolyze to form hydroxides.

- Coagulation: These hydroxides neutralize the charges on suspended particles, oils, and emulsions.

- Floc Formation: Pollutants clump together into larger flocs.

- Separation: Flocs settle or float, allowing for easy removal via filtration or flotation.

Advantages of Electrocoagulation

- No chemical dosing: Coagulants are generated in situ

- Low sludge production: Easier handling and disposal

- Effective for complex effluents: Removes heavy metals, dyes, oils, and organics

- Compact and modular: Ideal for decentralized or mobile treatment units

- Eco-friendly: No secondary pollution or chemical residues

🏭 Industrial Applications of EC

- Textile & dyeing – Color and COD removal

- Metal finishing – Heavy metal removal

- Food processing – Oil and grease separation

- Pharmaceuticals & chemicals – Organic load reduction

- Municipal wastewater – Pre-treatment and polishing

Electrocoagulation uses sacrificial metal electrodes (typically aluminum or iron) to release coagulant ions directly into the wastewater. These ions destabilize emulsions, suspended solids, and heavy metals, allowing them to aggregate and settle efficiently.

Ideal for: Metal plating, textile, food processing, and oil-contaminated wastewater

Benefits

- Effective removal of TSS, turbidity, heavy metals, and oils

- No need for external coagulants or flocculants

- Lower sludge volume and easier dewatering

- Simple automation and low maintenance

🔗 Synergistic Integration for Maximum Impact

When combined, EO and EC form a robust, multi-stage treatment system that addresses both physical and chemical contaminants:

- EC removes suspended solids, oils, and metals

- EO oxidizes dissolved organics and colorants

- Together, they ensure regulatory compliance, cost efficiency, and sustainable operation

✅ Why Choose Aqozone?

- Proven expertise in ozone and membrane systems

- Eco-conscious, low-chemical designs

- Custom-built, industry-specific solutions

- Global presence and trusted partnerships

🏭 Industries We Serve with Advanced ETP Solutions

At Aqozone Industries, we specialize in designing and commissioning customized Effluent Treatment Plants (ETPs) that meet the unique challenges of diverse industrial sectors. Our systems integrate ozone, ultrafiltration, electrocoagulation, and electro-oxidation technologies to deliver high-efficiency, eco-friendly wastewater treatment.

🏭 Industries We Serve

- Textile & Dyeing: Color removal, COD/BOD reduction, ZLD

- Pharmaceuticals & Chemicals: Toxic organics and high-COD effluents

- Food & Beverage: Oil, grease, and organic load removal

- Metal Finishing: Heavy metal removal and sludge minimization

- Tanneries: Chromium and sulfide treatment

- Paper & Pulp: Lignin and suspended solids removal

- Automotive & Engineering: Paint, oil, and coolant treatment

- Municipal & Decentralized: Compact ETP solutions

- Agrochemicals & Fertilizers: Pesticide and nutrient control

- Refineries & Petrochemicals: Hydrocarbon separation and polishing

Why Industries Choose Aqozone Industries

- Tailored solutions for specific effluent profiles

- Modular, scalable, and relocatable systems

- Low sludge generation and minimal chemical usage

- Compliance with CPCB, PCB, and international standards